BEO SC 120 Stationary Concrete Batching Plant: High-Capacity and Quality

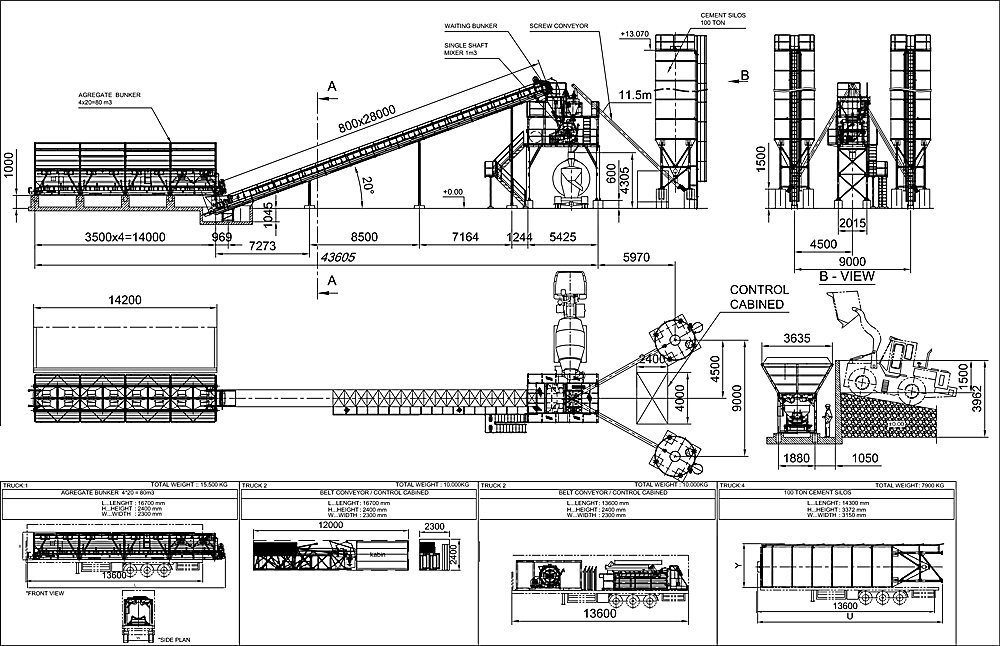

The BEO SC 120 stationary concrete batching plant is a powerhouse among stationary concrete plants, designed for producing top-quality concrete for large-scale construction projects and infrastructure endeavors.

With a robust capacity of 120 m3/hour, these fixed concrete batching plants operate fully automatically, covering concrete mixing, conveying, and unloading processes. Their exceptional designs enhance concrete quality, contributing to superior results in terms of strength, quality, and homogeneity.

These power plants are often deployed in the construction of major structures such as large bridges, dams, hydroelectric power stations, highways, and shopping malls. Their stability ensures on-time project delivery and high productivity.

Notably, BEO SC 120 stationary concrete batching plants are known for their environmental friendliness. They feature low energy consumption and minimal emission levels, making them the favored solution for sustainable projects worldwide.

Thanks to these exceptional attributes, BEO SC 120 stationary concrete batching plants are a frequently preferred choice within the construction industry.

Versatile Mixer Options for BEO SC 120 Concrete Batching Plants:

Rotary Mixer: These mixers operate by rotating the drum while mixing concrete. They are suitable for both small and large-scale projects, delivering high performance.

Static Mixer: In static mixers, fixed systems are employed instead of moving parts to mix the concrete. These mixers may be more cost-effective but offer comparatively lower performance.

Given that BEO SC 120 concrete plants are typically used for high-capacity projects, rotary mixers are the preferred choice. However, other mixer types can be accommodated based on customer requirements and project specifications.